Gold Ore Tailing Processing Plants

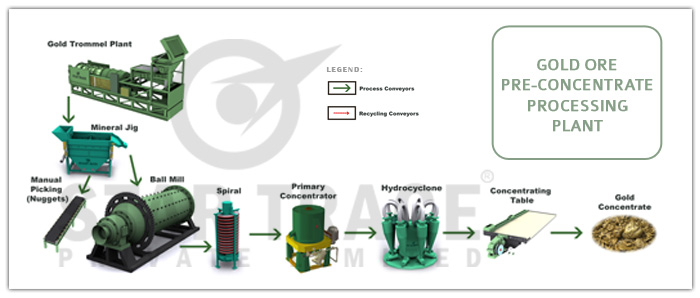

Gold ore tailing processing plant includes different types of process namely:

- Crushing

- Grinding Process

- Beneficiation

- Smelting

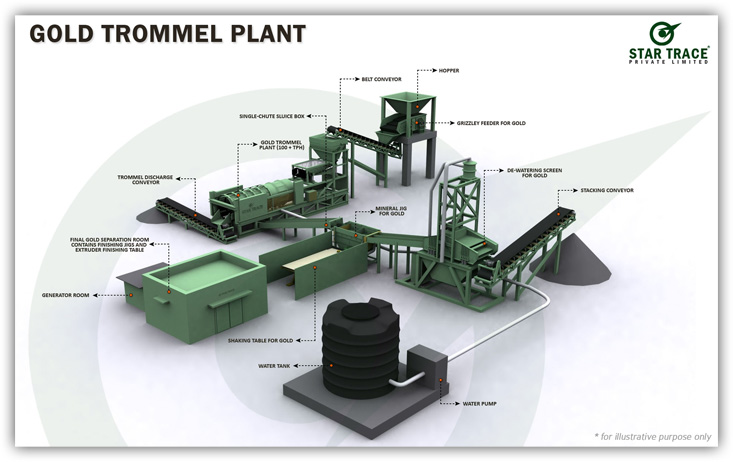

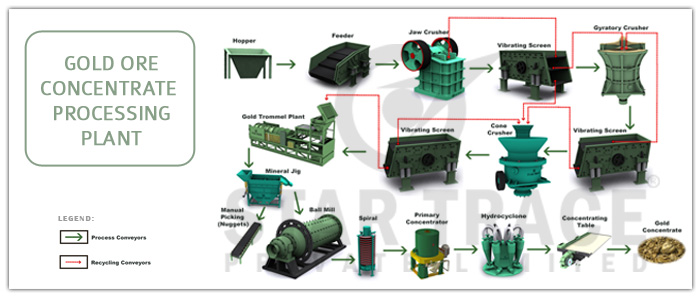

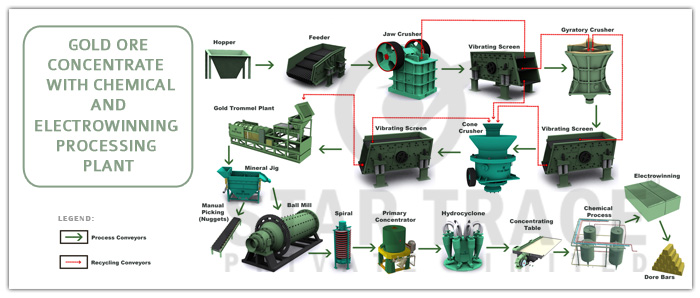

Gold ore tailing processing plants should be started with the feeder and it will take the extracted materials uniformly to the crusher for the first process. This process is used for resize and pulverize the gold ores into smaller than particles. For secondary crushing, conveyor will take these materials into the cone crusher. To separate unsized materials vibrating screen has been used and these materials again sent to the crusher for reach the desired size. After this process, the crushed gold ore should be grinded by using ball mill. The uses of beneficiation equipment is to remove the impurities from the gold ores. Gravity separator is used to remove the undesired material and the magnetic separator will remove the magnetic material from the gold ore. Finally through smelting, the high grade and pure gold ore can be obtained.

GOLD EXTRACTION FROM TAILINGS

Star Trace has been providing a standard technique for extracting the mineral contents from the mining tailings. Star Trace will start the process by sample testing through the mineral content of the tailings. After the successful result, Star trace will supply the equipment and training process to extracting the mineral concentration. And also we will provide the client for the concentrated extraction. Tailings is always an unnecessary byproduct of the mining from an environment. The damaging materials into surrounding soil have leach environmentally by these tailings are also left in the piles.

This process is mostly affects the water tables and wildlife for years to come. Star Trace process radically reduces the acid forming in the content of mineral by tailings using the extraction process of mineral. Thus, in the result of the tailings of the cleaner and the process of extraction in the significant amounts of the invaluable minerals. By using our products it provides the profit to the clients and our technology is use to stop damage to the environment.

Gold Extraction from Tailings Consist of following method:

- Gravity Separation

- Flotation

- Leaching - Cyanidation

- Electrowinning

Gold ore tailing processing plants should be started with the feeder and it will take the extracted materials uniformly to the crusher for the first process. This process is used for resize and pulverize the gold ores into smaller than particles. For secondary crushing, conveyor will take these materials into the cone crusher. To separate unsized materials vibrating screen has been used and these materials again sent to the crusher for reach the desired size. After this process, the crushed gold ore should be grinded by using ball mill. The uses of beneficiation equipment is to remove the impurities from the gold ores. Gravity separator is used to remove the undesired material and the magnetic separator will remove the magnetic material from the gold ore. Finally through smelting, the high grade and pure gold ore can be obtained.