Vibrating Equipments- Circular Motion Screen

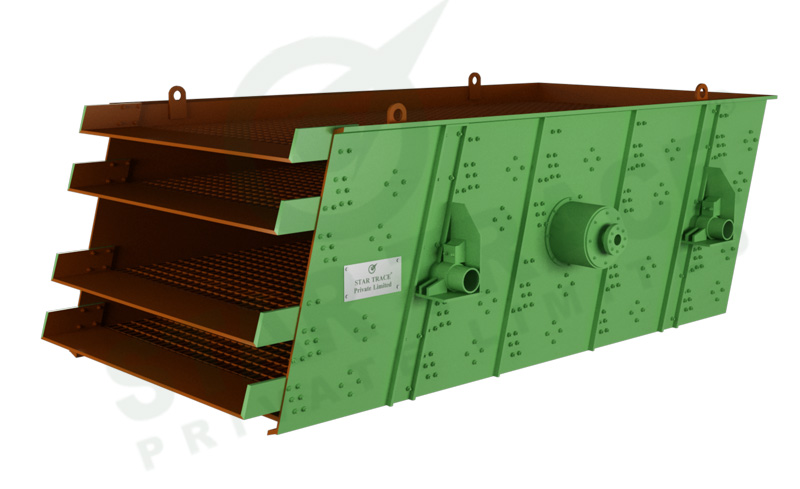

CIRCULAR MOTION SCREEN

The Type Universal Vibro Screen is a new generation vibratory screening machine characterized by low profile, efficient protection of support structure from vibrating masses and virtually noiseless operation. The various versions of these Vibro Screens permit its Use for wet and dry screening, coarse and fine Separations and are widely used in steel mills, mineral Beneficiation plants, chemical, mining, food and Fertilizer industries, coal preparation plants and many others.

The vibrating screen consists of screen box, supporting device, vibration exciter, transmission part. The barrel-type vibration exciter is installed in the middle part of the machine. During normal operation, the vibration of exciter will drive the screen mesh fixed on the screen box vibrate, and then materials will be screened.

This machine are mainly used in chemical industry, power station, steel works, coal plant, mine, building sites, etc,. Our scalping screen can be customized to meet various requirements. High-quality and safe operations. With single or multiple screen decks. Sand and gravel, building materials minerals, ores, pellets, sinter coal, coke, lignite, limestone, dolomite, chemical products, fertilizers.

The vibrator Unit is a steel shaft, completely housed in a protective steel tubular casing which in turn is provided with an easily replaceable rubber cover to resist damage and abrasion. Balance Weights are keyed to shaft. The bearings are specially designed for the use on screens and are a high capacity self aligning double roller type.

These bearings have special tolerances and improved lubrication facilities to give extended bearing life under their ardous working conditions. Labyrinth type grease sealings are provided to prever dust getting into bearings. A deep groove V-belt Pully is bored eccentrically to ensure true running arn to obviate the belt whip.

The Circular Motion Screens are bolted single or multi deck structure with a substantial and rigid design. The screen body consists of the two side plates with bolted transverse supports and screen mounts. The screen box is based on an open design. Drive shaft with its eccentric weights runs in heavy duty self-aligning roller bearings. The throw of the vibrating screen is varied by adjusting the eccentric weights.

The drive is either direct or through cordon shaft and v- belts. The vibrating screen is supported above the substructure by means of helical coil compression springs. The screen installation angle can be varied to suit the application. There are several options for lubrication, oil or grease, which can be used without modification. Selected bearing seals ensure a long service life.

A Type Circular Motion Vibrating Screen is consisted of Screen box, Screen, Vibrating motor, Reducing setting and Base plate. The angle of the screen could be changed by the adjustment of the height of the base plate. Usually the vibrating motor is fixed on the right side of the screen frame. We have all sorts of screens for our users to choose.

WORKING PRINCIPLE OF VIBRATING SCREEN:

- The two same vibrating motors which rotate synchronously in different directions, making the screen body do periodical to-and-fro linear moving to achieve screen classification purpose.

- The crossbeam and side boards of screen are made of stainless steel plate or heat-resisting plate and connected by the rivets to decrease internal stress and make good fastness.

OTHER CONTENTS:

Circular motion (Single-shaft) screens. When the shaft of an inclined screen is located precisely at the screen's centre of gravity, the entire screen body vibrates with a circular vibration pattern. Occasionally, the shaft is installed above or below the center gravity as in the system this placement result in an elliptical motion, slanting forward at the feed end. A circular motion at the center; and an elliptical motion, slanting backward at the discharge end. Forward motion at the feed end service to move oversize material rapidly out of feed zone to keep the bed as thin as possible.

This action facilitates passage of fines which should be completely removed in the first one-third of the screen length. As the oversize bed thin down, near the center of the screen, the motion gradually changes to the circular pattern to sow down the rate of travel of the solid. As the discharge end, the oversize and remaining near-size material subjected to the increasingly retarding effort of backward elliptical motion. This allow the near-size material more time to find openings in the screen cloth.

The following are the features of Vibratory Motor:

- Quick changing of screen mats and of the specially developed removable names, to allow lengthwise tensioning using simple screw connections.

- The machine is economically Equipped to customer's requirements with screen decks made of spring steel wire perforated sheet wire Perforated sheet metal, rubber or polyurethane optimum untilization of the screening area by a deck arrangement which is adapted to suit the grain size concerned, namely longitudinal, transverse, inserted and laid linings.

- Low noise level with grease lubricated circular drive units which run extremely quiet and are of a stable design with low harmonic oscillation.

- High availability and operational reliability is the result of a highly Developed design and quality Standard.

- Low maintenance costs resulting from a direct drive using a normal commercial motor and maintenance free card an shaft.

- Easy, quick installation and removable of worn and replacement parts by the use of screw connections.

Our scalping screen can be customized to meet various requirements. High-quality and safe operations. With single or multiple screen decks.

- Sand and Gravel

- Building materials

- Minerals

- Ores

- Pellets

- Sinter coal

- Coke

- Lignite

- Limestone

- Dolomite

- Chemical products

- Fertilizers

This machine are mainly used in:

- Chemical industries

- Power stations

- Steel works

- Coal plants

- Mine

- Building sites

| Type | Decks | Capacity (m3/h) | Motor power KW |

Decks Spec. (mm) |

Total weight (Kg) |

Dimensions (L*W*H) mm |

| STR1225 | 2 | 8-60 | 5.5 | 1200*2500 | 3500 | 3040*1840*800 |

| STR1225 | 3 | 10-70 | 5.5 | 1200*2500 | 3850 | 3040*1840*1200 |

| STR1230 | 2 | 12-78 | 7.5 | 1200*3000 | 4200 | 3390*1900*800 |

| STR1230 | 3 | 13-80 | 7.5 | 1200*3000 | 4600 | 3537*1900*1200 |

| STR1237 | 2 | 15-86 | 7.5 | 1200*3700 | 4600 | 4090*1900*800 |

| STR1237 | 3 | 16-90 | 7.5 | 1200*3700 | 5200 | 4400*1950*1200 |

| STR1535 | 2 | 20-125 | 11 | 1500*3500 | 5890 | 4552*2250*900 |

| STR1535 | 3 | 21-125 | 11 | 1500*3500 | 6700 | 4552*2250*1600 |

| STR1545 | 2 | 22-150 | 15 | 1500*4500 | 6330 | 5400*2250*1600 |

| STR1545 | 3 | 22-150 | 15 | 1500*4500 | 6800 | 5400*2250*1700 |

| STR1548 | 2 | 22.5-162 | 15 | 1500*4800 | 6980 | 5300*2200*860 |

| STR1548 | 3 | 22.5-162 | 15 | 1500*4800 | 7600 | 5752*2200*1600 |

| STR1848 | 2 | 25-206 | 15 | 1800*4800 | 9080 | 6140*2470*1380 |

| STR1848 | 3 | 32-276 | 18.5 | 1800*4800 | 9600 | 6140*2710*1780 |

| STR1854 | 2 | 32-312 | 18.5 | 1800*5400 | 10150 | 6500*2600*1300 |

| STR1854 | 3 | 32-312 | 22 | 1800*5400 | 10840 | 6960*2600*1630 |

| STR2160 | 2 | 50-475 | 30 | 2100*6000 | 11780 | 7300*2950*2000 |

| STR2160 | 3 | 50-475 | 30 | 2100*6000 | 12800 | 7300*2950*2000 |

| STR2460 | 2 | 65-550 | 37 | 2400*6000 | 15600 | 7450*3230*1500 |

| STR2460 | 3 | 70-620 | 37 | 2400*6000 | 17600 | 7450*3230*1910 |